Grouting plays a major role in maintaining any construction’s structural integrity, stability, and durability. It is the process of injecting a pasty material into the structure to improve its physical characteristics. Numerous grouting options are available in the industry, among which urethane grout provides excellent resistance and durability. Here is a detailed look at urethane grout and everything you need to know about it.

What is Urethane Grout?

Urethane grout is a type of grout made using polyurethane resin and cementitious materials. It is an alternative to traditional cement grouting, as it is cleaner, faster, and less disruptive than cement grout. This is most commonly used to repair and stabilise concrete structures, improve structural integrity, and prevent further damage.

Benefits of Urethane Grout

Flexibility

This highly flexible grout allows the structure to resist minor movements and vibrations without chipping and cracking. It is ideal for structures prone to stretching, twisting, compression, and fluctuating temperatures.

Adhesion

The polyurethane grout provides strong adhesion to most tiles, stones, ceramics, glass, porcelain, and more. This strong bond between the tiles, concrete, and stones prevents the structure from developing cracks or damage.

Waterproof

Urethane grouts are non-porous and highly resilient to water and moisture. This grouting completely seals gaps and cracks and creates a barrier to prevent water from affecting the structure.

Chemical Resistance

PU grout is highly resistant to acids, alkalis, solvents, cleaning agents, and other chemical agents. Thus, it is suitable for exposed structures and marine environments.

Fast Curing

Urethane grouting requires less curing time, which improves the installation and repair speed. The quick setting time makes the structure functional immediately and doesn’t affect foot, machine, or vehicular traffic.

Durability

Urethane grouts are highly durable and superior to other grouts. They can withstand compressive and flexural strength and have good chemical, water, impact, and abrasion resistance. All these properties prevent the structure from distortion and improve the lifespan.

Applications of Urethane Grout

Soil Stabilization

PU grouts are most commonly used to stabilise construction sites. They are injected into the sand to improve the soil’s load-bearing capacity, especially in areas that require quick stabilisation and are water-prone areas.

Waterproofing

Urethane grout is non-porous and highly effective for waterproofing applications. This grout can stabilise soils and structures exposed to water and provide a water-resistant layer. It is used to repair water-prone structures such as basements, tunnels, dams, and marine structures.

Void Filling

This grout is injected to fill voids in concrete structures such as slabs, walls, and damaged or abandoned structures, improving stability and providing additional support. The filling of gaps prevents the surface from debris and dirt.

Seal Cracks and Joints

PU grout plays an important role in repairing existing structures, such as sealing cracks and joints. It is an excellent adhesive material that binds the cracks or joints and prevents the structure from causing further damage.

Re-level Slabs

Polyurethane grouting is best suited for lifting large and heavy slabs. It has a high expansion force and can spread large areas of the slabs with minimal injection holes. Thus, lifting roads, bridges, rail crossings, and heavy-load slabs in industries and commercial spaces can be done.

Materials Used for Installing Urethane Grout

The materials used for installing urethane grouts include:

- Urethane Grout: It can either be pre-mixed or in powdered form.

- Epoxy/ Rubber Grout Float: It cleans and smoothens the grout and tile surface.

- Sponges and Microfiber Cloths- They clean the excess grout on the tile surface for a polished finish.

- Injection Pump: This pump applies or injects epoxy grout to joints or gaps.

- Drilling Machine: It drills the injection ports to seal the cracks.

- Water: Used to activate the grout.

How to Install Urethane Grout?

Surface Preparation

Ensure the tile surface is clean, dry, and free from dust, debris, and other contaminants. Dampen the surface with clean water to prevent the grout from binding to the tiles.

Mixing

Mix the powdered urethane with cementitious material to make it a pasty, homogenous substance. If the grout is pre-mixed, ensure it is well stirred and has the right consistency for grouting.

Applying Grout

Apply the grout between the tiles using a rubber grout float. The process should be done diagonally across the surface, and the grout should be pressed into the joints without any air voids.

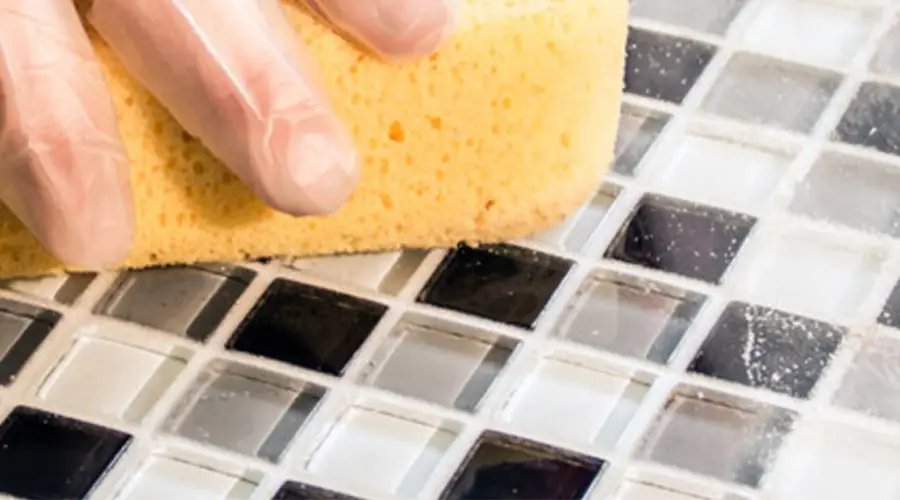

Cleaning

After applying the grout, clean the tile surface using a sponge or microfiber cloth to remove excess grout before it cures. The cleaning process should be done carefully to avoid pulling the grout off the joints.

Curing & Final Cleaning

After initial cleaning, allow the grout to set for 10 to 20 minutes for the initial setting. Use the wet sponge to wipe away the haze formed on the tile surface. Repeat the process until the hazes formed on the tile surface is cleaned. After final cleaning, leave the surface to cure for 24 hours to attain maximum hardness and resistance.

Cleaning and Maintenance of Urethane Grout

- Avoid harsh cleaning chemicals on the surface, as they may cause damage over time.

- Frequent cleaning should be done to prevent dust, dirt, spills and debris on the surface.

- Use natural cleaners, such as oils, enzymes and soft, soapy water to clean the surface.

- Use a soft scrub, sponge, or microfiber cloth to wipe away stains and dust.

Conclusion

Urethane grout is highly resistant and durable, helping maintain structural integrity. It is widely used for filling voids, cracks, and joints, lifting slabs, stabilising ground surfaces, and fixing tiles. Although it can be expensive and requires skilled workers, PU grouting provides numerous benefits and helps improve the structure’s lifespan.

FAQs

Yes, urethane is extremely water-resistant, which protects the structure from all kinds of water intrusions and moisture. This grout is widely popular for its use in water-prone areas.

Urethane grout is highly durable and has an expected lifespan of ten to twenty-five years. However, the lifespan depends on usage, atmospheric conditions, and material quality.

Yes, urethane grout possesses good flexibility and weather resistance, thus making it suitable for outdoor applications.