Footing is an essential component of constructing structures in the construction industry. Precast footing comes in various forms to improve structural integrity and shorten project timelines. Such precast concrete footings can be constructed following the project parameters. Experienced builders and engineers can choose the best footing to excel in their construction projects. While using different kinds of precast footings, several elements should be taken into account to achieve the best performance and longevity. Now, let us take a short look at the precast concrete footings overview.

What are Precast Concrete Footings?

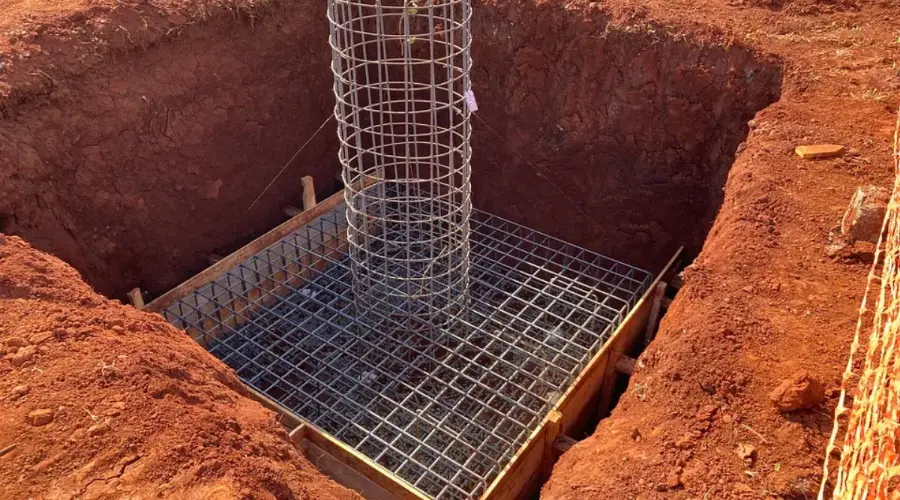

A pre-made concrete foundation can be manufactured in a regulated factory set-up. These footings are typically cast using the moulds to achieve desired sizes and shapes as per the project requirements. These moulds are thoroughly washed and reused after completing one set of processes. Once curing is completed, these cast precast concrete footings are removed from the moulds using lifting equipment or cranes, ensuring a safe and smooth extraction process. Finally, they are transported to the construction site to provide a solid foundation or base for bridges, buildings, or other structures.

Types of Precast Concrete Footings

Precast concrete footings come in a variety of styles, each tailored to specific structural requirements:

1. Pad Footings (Isolated Footings)

- Rectangular or square concrete pads designed to support individual columns or structural elements

- Typically used for lighter loads and structures with well-defined load distribution

- Prefabricated off-site and transported to the construction location

- Provide good load transfer and stability for small to medium-sized buildings

2. Strip Footings (Continuous Footings)

Long, linear precast concrete elements used to support load-bearing walls or a series of closely spaced columns

- Distribute loads along a continuous line

- Ideal for structures with linear load paths like residential buildings, warehouses, and commercial structures

- Can be manufactured in various lengths and widths to suit specific structural requirements

3. Raft Footings (Mat Foundations)

- Large, continuous concrete slab that covers the entire building footprint

- Designed to spread loads evenly across the entire foundation area

- Particularly useful in areas with weak or inconsistent soil conditions

- Precast in sections or as complete units for easier transportation and installation

- Provides excellent load distribution and reduces potential differential settlement

4. Pile Caps

- Precast concrete elements that sit atop foundation piles

- Connect and distribute loads from structural columns to deep foundation elements

- Critical in areas with challenging soil conditions or high structural loads

- Can be manufactured in various shapes and sizes to accommodate different pile configurations

- Wider at the base to distribute structural loads over a larger area

- Typically used when soil bearing capacity is moderate

- Precast to ensure consistent quality and faster installation

- can be designed with reinforcement to handle specific load requirements

- Used when two or more columns are close together or have overlapping load zones

- Precast as a single unit to efficiently transfer loads from multiple structural elements

- Helpful in situations with property line constraints or irregular column spacing

Application of Precast Concrete Footing

Precast footings are known for their unique properties and benefits that are utilized in various common construction applications, including the following:

- As precast concrete footings provide a stable foundation, they are commonly used to construct standalone residential buildings, especially in areas with poor soil conditions. Many construction professionals prefer these pre-made footings to ensure timely project completion.

- For building warehouses, commercial hubs, and factories, these precast footings are used due to their strength and durability to withstand heavy loads for many years.

- Precast concrete footings are indeed used in heavy infrastructures such as bridges and roads. They are valued for their ability to handle significant loads due to their high compressive strength and precision manufacturing.

- Utility structures like poles, transformers, and communication towers can be built using precast concrete footings.

Advantages of Precast Concrete Footings

Precast concrete footings provide numerous advantages and conveniences in construction projects for contractors and designers utilising these pre-manufactured components. Their primary assistance in construction projects includes:

- Quality Control: Since precast footings are manufactured in a factory with a regulated environment, strict quality checks are performed to ensure they meet the required strength and durability standards.

- Faster Installation: As they are casting off-site, they significantly reduce the time required for onsite pouring of concrete. Thus increasing the speed of the project timeline.

- Cost-Effective: These pre-made concrete footings typically require less manpower and reduce labour charges compared to cast-in-place footings.

- Resilience and Sturdiness: Precast footings can endure heavy loads, significant stress, and challenging weather conditions across different seasons.

- Resourceful: The variety of sizes and designs available for precast concrete footings makes them suitable for a wide range of construction applications.

Key Considerations When Using Precast Concrete Footings

While precast concrete footings provide numerous benefits, several key considerations must be kept in mind:

- Site Accessibility: Precast footings require more space and ease of transportation on the construction site for timely delivery. As they are huge, they necessitate specialised equipment and vehicles for transportation. Make sure to pave easy access for heavy machinery and transportation of precast concrete footings in the construction area.

- Load-Bearing Capacity: Each type of footing is cast as per the project requirements. It’s essential to determine the load-bearing requirements of the structure before choosing the type of precast footing. Not all footings are designed to handle the same weight or conditions.

- Soil Conditions: Footings are made as per the condition of the soil at the construction site. According to the soil type, additional reinforcements are required while casting precast footings to provide more strength and longevity for the structure. Customisation is made as per the soil condition.

- Transport Logistics: To minimise any delay or damage, precast concrete footings are transported with specialised vehicles.

Installation of Precast Concrete Footings

The placement of preformed concrete bases generally adheres to a structured procedure.

- Groundwork and Clearing: The site requires excavation, leveling, and the removal of debris to create a stable base for installing precast concrete footings.

- Positioning the Footings: As they are large and need much attention while handling the concrete footings, huge cranes and other heavy equipment are required to lift them. They are temporarily fixed and positioned accurately according to the layout plan.

- Jointing and Securing: Specialised connectors or reinforcement bars are used to secure the vertical and horizontal joints between the precast elements once they are placed.

- Examination and Quality Assurance: A thorough examination is held to ensure that the footings are properly aligned and secure after perfectly securing the precast footings.

Maintenance and Longevity of Precast Concrete Footings

Precast concrete footings are known for their longevity and minimal maintenance needs.. Routine inspections are required to maintain their ideal shape as follows:

- Examine for cracks: Small cracks may develop in concrete over time as a result of settling or movement and should be monitored and repaired as needed.

- Check for Damage from Moisture: Over time, excessive moisture or water intrusion can erode concrete. To avoid water accumulation, make sure the drainage surrounding the footing is adequate.

- Sealing and Cleaning: Regular cleaning of the footings helps remove impurities and debris. Sealing the concrete adds an extra layer of protection against weather conditions.

Conclusion

Precast concrete footings are an excellent choice for providing strong foundations. They are steady, durable, and efficient. Their high quality, low cost, and quick installation make them a top choice for many construction projects. Builders can ensure a strong foundation by using their expertise. Builders should have a clear understanding of the types, applications, and key considerations for precast concrete footings. With proper care, these footings offer long-term stability, reliable support, and durability that can last for many decades.