Grounding systems are an indispensable part of constructing and maintaining electrical systems. A grounding system ensures the prevention of electrical shocks, protects equipment from damage, and maintains the integrity of electrical circuits. The system is incorporated in all forms of construction projects such as residential, commercial, and industrial setups. This prevents catastrophic outcomes including fires, system outages, and life-threatening hazards. For any construction professional, knowledge about components, types, and applications of grounding systems is essential. This article will be a small introductory guide on grounding systems, their significance, installations, and maintenance. This will provide readers with a comprehensive understanding of the role of grounding systems in construction.

What is a Grounding System?

It is a low-resistance path that carries an electrical flow into the ground. This connection of electrical equipment with the ground is called grounding. This enables a safe flow or discharge of excessive currents to the ground without damaging or causing any safety hazards to the environment or nearby people. In technical terms, the term grounding can be described as a type of conductive connection between the electrical equipment and the ground. The inheritance of earthing conductors in the construction industry protects the volatile power supply. The absence of a grounding system means you are risking your data centre equipment and people’s lives.

Types of Grounding Systems

There are three types of grounding systems; they are,

1. Ungrounded Systems

2. Resistance Grounded Systems

3. Solidly Grounded Systems

Ungrounded Systems: This type of grounding system was much more common in the 40s and 50s. As the name suggests, this type does not imply that the system is a standalone, not having a connection to the ground. What it means by the term ungrounded is that there is a capacitance between the electrical lines and the earth. In electrical terminology, this system is called capacitance-grounded system. As a result of this capacitance, the ground-fault current is negligible. This system is considered to be riskier despite its existence and purpose fulfilment.

Resistance Grounded Systems: In this system, electrical power systems connect a neutral line to the ground through a resistor. Through a neutral line, this resistor will limit the fault current. This system is further divided into two based on the resistance; they are high resistance grounding and low resistance grounding. This high-resistance grounding limits ground-fault level to <10 amps. The low-resistance grounding limits the ground-fault current to between 100-1000 amps.

Solidly Grounded Systems: In this system, the electrical power is directly connected to the ground. In this type of system, it is much easier to locate than the other two systems. The industrial sector uses this system as a backup for generators. It reduces all the possibilities of overvoltage and prevents any short circuit or mishap.

Components of a Grounding System

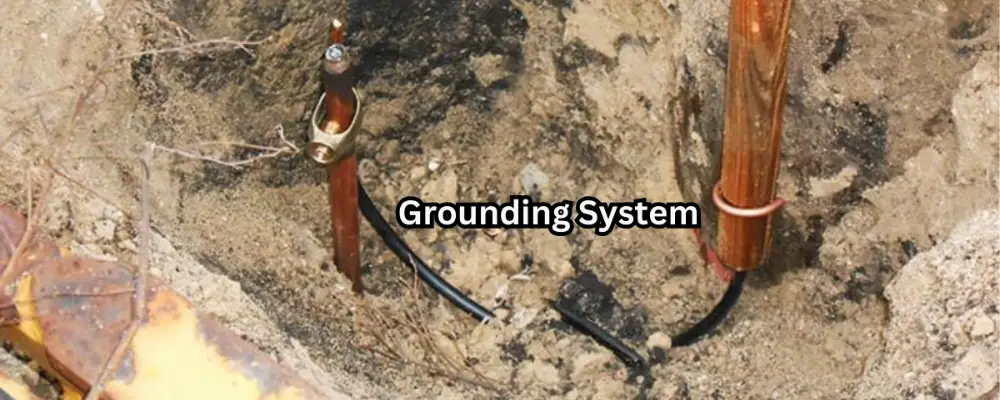

Some of the main components involved in the grounding system are ground rods, grounding conductors, grounding plates, grounding electrode systems, and bonding conductors.

- Rods that provide a connection to the ground are known as ground rods.

- Wires that connect the electrical system to the ground rods are called grounding conductors.

- Whenever the ground is not suitable for driving rods, grounding plates are used.

- Besides, we have a grounding electrode system that serves as interconnected components that establish a grounding connection.

- The inclusion of bonding conductors in the grounding system ensures electrical continuity and prevents potential differences.

Installation process of a Grounding System

The design and installation of the grounding system involves seven steps. Below are the procedures that need to be followed for the installation of the grounding system.

- The first step in any grounding system is to measure the soil-specific resistivity. This can be measured with the help of 4 piles using the Wenner Method. All four piles are driven into the ground at equal intervals and in the same direction. With the use of a ground megger, the earth’s resistance is calculated.

- Grounding rods are used in those areas where the ground is not rocky. In this step, as the rods reach the moist layers of the soil, it becomes possible to get low grounding resistance.

- The next step is to ensure grounding cable connections with the rod. This is done by combining vertical rods with bare-stranded copper conductors.

- Underground connections can either be conductor-to-conductor or conductor-to-electrode. To ensure these connections are stronger than mechanical connections, the Thermowelding method is used.

- If the desired level of grounding resistance cannot be achieved, grounding resistance-reducing materials are added.

- To measure grounding resistance and control grounding rods, grounding manholes are used.

Testing and Maintenance of Grounding Systems

Periodic testing and maintenance of grounding systems are essential to ensure their effectiveness. In testing the grounding system, measuring ground resistance and inspecting connections for corrosion or wear are important. Some of the common methods are:

- To measure earth resistance, tools like clamp meters can be used.

- To ensure all components are properly connected, continuity testing is carried out.

- Apart from these methods, visual inspections for physical damage, replacing damaged corrections, and verifying compliance with updated codes can detect and rectify issues.

Applications of Grounding Systems

- Installation of a grounding system can protect homes from electrical faults and lightning strikes.

- In industrial facilities and commercial establishments, it safeguards sensitive equipment and prevents power disruptions.

- In telecommunication towers, it prevents antennas and other equipment from being struck by lightning.

- The usage of a grounding system in renewable energy systems stabilizes solar panels and wind turbines against electrical surges.

Conclusion

As a result, grounding systems are very important components for any secure electrical system. They greatly reduce the risks associated with electrical shocks, damage to equipment, or failure of a system by supplying a low-resistance pathway through which electrical current can flow into the earth. Every construction specialist must know what the various types of grounding systems are, their components, and how to install and maintain them. Proper grounding methods greatly contribute to the safety of the dwelling’s occupants, the integrity of significant equipment, and the elements of the electrical system’s infrastructure.