The construction process of residential or commercial buildings does not just end with the accurate arrangements of materials and sturdy foundations. It must incorporate a visually striking masterpiece to set your structure apart from the ordinary construction work.

When it comes to aesthetic appeal, you need to consider pointing in priority. It improves the structural integrity and overall appearance of the building. They are a suitable choice for achieving the desired finish in brick and stone masonry construction. Among the several pointing types, we are about to discuss flush pointing. Let us continue the reading to explore its meaning, purpose, and advantages it serves.

What is Flush Pointing in Stone Masonry?

Flush pointing is extremely durable and is a widely used type in construction. This process involves filling the raked mortar joints with fresh mortar, resulting in a smooth and seamless finish. The mortar that is flushed between the two stones or bricks eliminates the collection of water and dust in between the spaces. It helps enhance the cleanliness and longevity of the structure.

Purpose of Flush Pointing in Stone Masonry

The flush pointing in stone masonry serves two important purposes. They are:

Protection: Flush pointing efficiently seals the gaps or cracks that exist between the stones, protecting the structure from adverse effects of snow, humidity, and other harsh environmental conditions. While filling the joints with fresh mortar, the structural integrity of the masonry is enhanced, which typically prevents corrosion and other damages.

Aesthetic Value: As stated earlier, flush pointing creates a smooth and seamless finish on the surface, making it look cleaner and polished. It naturally highlights the patterns and textures applied to the stone.

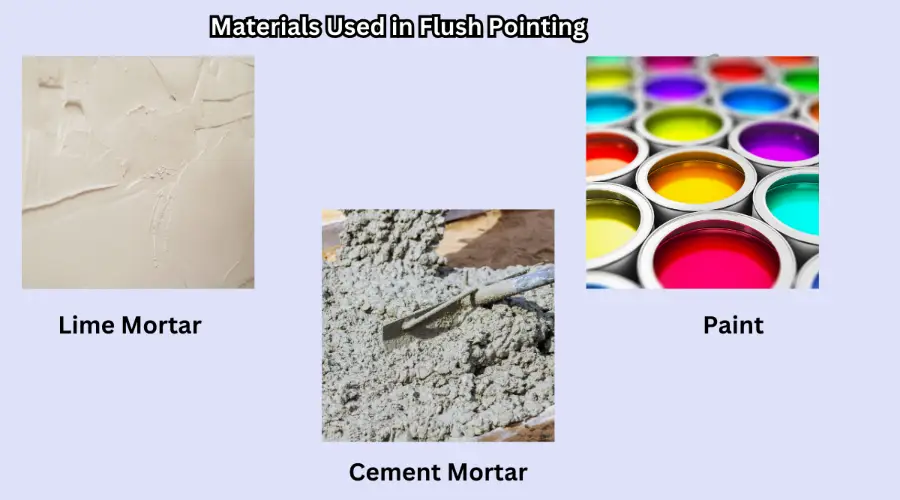

Materials Used in Flush Pointing

These are the significant materials used in flush pointing, including:

Lime Mortar: It is typically used to reduce shrinkage and cracking. It is one of the softer materials often used in brick or stone masonry work. Lime mortar efficiently maintains the structural integrity of the construction by allowing moisture to move through the joints.

Cement Mortar: Another essential material composed of cement, sand, and water, it enables the building to be strong and durable, used for different types of masonry work. The recommended ratio of cement to sand is 1:3.

Paint: Paint is an added material to create a rustic look for the traditional mortar pointing. It transforms the entire look of the room, commonly used on ceilings and woodwork.

Process of Flush Pointing

Flush pointing is the most commonly used construction technique. This technique involves filling the mortar joints with fresh mortar to create a smooth and perfect finish.

Here are the simple steps involved in flush pointing:

Remove Existing Mortar: The old, deteriorated mortar that exists between the stones of bricks should be removed to ensure a strong bond with new mortar. IT is essential to ensure the gaps are thoroughly cleaned without any excess mortar, dust, or debris.

Mortar Preparation: Prepare a new mortar in appropriate proportions of cement, sand, water, and lime. The consistency should be properly workable and can be easily applied over the joints or gaps of the stones.

Fill the Gaps: Apply a newly prepared mortar into the raked joints and ensure the voids are completely filled. Once you level the surface, gently remove the excess mortar to create a clean, seamless surface.

Finishing: To enhance the appearance of the whole space, create a smooth and uniform finish over the surface. The mortar at the right consistency can allow you to create specific textures or patterns, enhancing the overall atmosphere of your home.

Advantages of Flush Pointing

Due to its exceptional advantages, flush pointing is used in several applications. Here’s a breakdown of some of its significance:

Excellent Durability: While sealing the gaps between stones or bricks, you can reduce water penetration and prevent the risk of mould growth, structural degradation, and frost damage. A well-pointed wall resembles the strong bond that exists between individual stones.

Low Maintenance: You might be afraid that the flush pointing needs regular maintenance to extend its durability. Luckily, this is wrong. Maintenance is quite easy; removing dust and grime buildup is enough to improve the lifespan of the structure.

Unique Appearance: More than being durable, flush pointing involves improving the overall look of the structure. The creation of a smooth and perfect surface with no gaps or voids filled. It is a quite natural way that contributes to achieving the desired pattern and texture of the stonework.

Energy Efficiency: Flush pointing is a low-energy consumption method and also improves the thermal performance of the overall building. It is suitable for small- and large-scale construction, providing aesthetic appeal and long-term preservation.

Disadvantages of Flush Pointing

Flush pointing has some potential drawbacks, which are listed in the following:

Less Water Resistance: Flush pointing may fill the gaps and prevent water penetration inside the wall, but it may not be water-resistant in harsh weather conditions. When it is exposed to heavy rain, it can be susceptible to moisture and water penetration.

Complex Repairing: The maintenance of flush pointing might be easier, but the repair or replacement may compromise the original colour and texture of the mortar, particularly if the structure is old or ancient.

Cracking and Shrinkage: Mortar proportions are crucial for strong and durable bonding. Ensure it is properly mixed and applied between the stones; otherwise, it can lead to cracks and shrinkage in the pointing.

Maintenance of Flush Pointing

Regular maintenance is advisable to improve the effectiveness and longevity of flush pointing. Here are some maintenance tips provided for your reference:

- Conduct periodical inspections to pinpoint the signs of damage like chips, loose mortar, or cracks. Timely repairs can cost less and prevent further deterioration.

- Repointing is not recommended as it can significantly impact the originality of pointing. If it is necessary, consider hiring a professional mason to retain the integrity.

- It is suggested to use a pressure washer or soft brush to clean the dust and dirt from the masonry surface. Avoid applying harsh chemicals that cause damage to the stone or mortar.

- Consider applying a water-repellent coating to withstand harsh weather conditions and prevent moisture damage.

Final Thoughts

Flush pointing is crucial for construction as it promotes structural integrity, longevity, and aesthetic appeal with reduced maintenance. Choosing high-quality materials and professional masonry workers ensures better results. Follow the steps mentioned in this article to avoid any difficulties while filling with fresh mortar.