Achieving better performance in an eco-friendly and cost-efficient way is the most demanded modern construction need. This plays a vital role in the selection of concrete. However, the market does not have much concrete that ticks all the checkboxes. This is where dry mix concrete plays a major role, as it satisfies almost all the requirements. Here, we look at dry mixing, its application, its pros and cons, and everything you need to know about it.

What is Dry Mixing of Concrete?

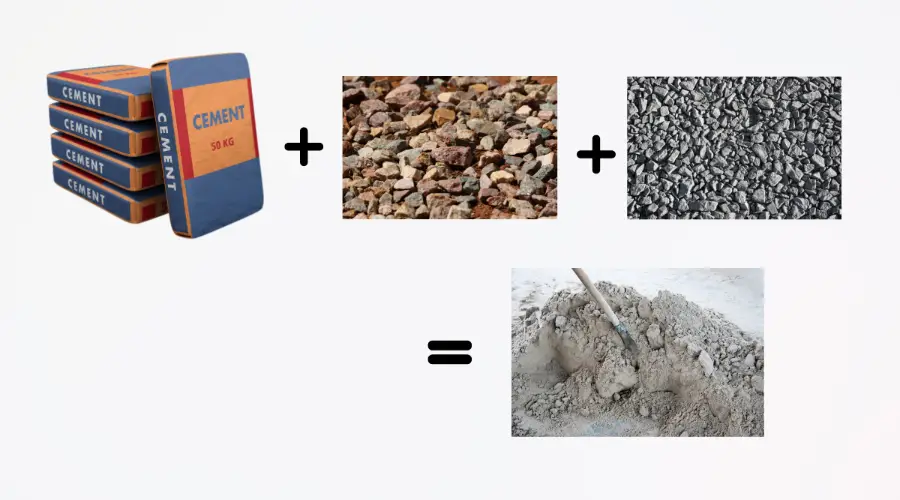

Dry-mix concrete or dry-batch concrete is a mixture of cement, sand and coarse aggregate in a dry state without mixing water. Due to the low water content in concrete, it is widely used in water-prone areas, where it acquires the water content required to bind the mortar. This type of concrete is commonly used in construction that is in contact with the ground.

Application of Dry Mixing of Concrete

- It is most commonly used for constructing substructures and sleepers, as it can use groundwater to bind the mortar.

- This concrete is ideal for building a foundation and trench filling.

- It is used to build base layers of roads, driveways, and paving stones.

- It can be used as grouting material for laying tiles.

- It can be used for flooring the building.

- It is ideal for repairing concrete structures and providing reinforcements.

Advantages & Disadvantages of Dry Mix Concrete

Advantages

- Despite having less cement in the mixture, they have high strength & durability, providing stability and structural integrity.

- It can withstand heavyweights and resist deformation.

- It can be used for external structures as it can withstand harsh weather conditions.

- Compared to other concrete mixtures, dry mix is cost-effective, requiring less labour and cement.

- The dry mix can be bagged and stored on-site for a long time and used when required.

- Since the dry mix is pre-mixed and bagged, it is easy to use, reducing the need for on-site machinery.

- The usage of dry mix increases the speed of the construction. The lack of water in the mixture reduces the curing period, resulting in rapid progress in construction.

- The low usage of cement reduces the carbon footprint, and using natural sources as aggregates makes it an eco-friendly concrete option.

- As dry mix concrete is made under regulated conditions, it has high quality & consistency.

- It minimises the need for excess material and reduces waste production caused by on-site mixing.

Disadvantages

- Dry mix is unsuitable for large-scale complex structures due to its quick setting time and it cannot be reused after it has set.

- It requires adequate water on-site due to the mixture’s low to zero water content.

- This mix is not applicable for all types of construction, limiting its usage to structural purposes and not for aesthetic and surface finishes.

Material used in the Dry Mixing Process

Cement

Cement is the primary raw material used for the dry mixing process. It acts as an adhesive to blend with other aggregates and make the concrete mix into a workable form. Although a primary raw material, it is used in limited amounts compared to other aggregates in the mixtures.

Fine Aggregate

Sand is the most commonly used fine aggregate in the mixture of dry batch concrete mix. It provides a great bond with cement and helps improve the concrete’s strength. It is used six times more than cement in the mixture. Aggregates such as lime or fly ash can also be used as a fine aggregate.

Coarse Aggregate

Coarse aggregates, such as crushed gravel and stones and cement and sand mixtures, are used. The coarse aggregate is available in a higher quantity in the mix than sand and cement.

The ideal mix ratio of dry concrete mix is 1:6:12, where one part of cement, six parts of sand, and twelve parts of coarse aggregate are mixed.

Dry Mixing Process

Storing Raw Material

The first process of production of dry mix is storing the necessary raw materials, including cement, sand, and other additives, in storage containers or silos.

Batching

The raw materials are then weighed and batched based on the construction needs and type of structures that need to be built.

Mixing

The batched raw materials are mixed carefully according to the standard mix proportion of 1:6:12 or customised proportion. The raw materials are mixed using a special mixing machine, ensuring that the ingredients are distributed evenly and completely without any lumps.

Packing

After the dry mix of concrete, the concrete is packed into durable containers and bags and kept ready for shipping.

Quality Check

A sample of the dry mix concrete is tested to find the quality of the concrete to make necessary quality control measures. If the concrete lacks certain properties, additives can be added to achieve full efficiency.

Storage & Transporting

After the production and quality tests, the concrete is packed, stored and transported carefully to the construction site.

Conclusion

Dry mix concrete is a game changer in construction and masonry works. It provides numerous benefits and advantages, including improved quality, reduced labour, cost efficiency, and increased speed of construction. This concrete is also eco-friendly, reducing the carbon footprint. They are simple and easy-to-work concrete in the industry and are known for their usage in grounded and underground structures.

FAQs

Dry mix concrete is ideal for projects such as foundations, substructures, and road construction due to its high strength and durability. It is also suitable for applications like flooring and repairs where quick setting and low water content are advantageous.

In cold weather, dry mix concrete’s hydration process may slow down, potentially causing freezing issues, while hot weather can lead to rapid curing and cracking. Proper curing techniques and temperature control measures are essential to mitigate these effects.

Yes, dry mix concrete can be used for decorative applications such as stamped concrete, coloured overlays, and exposed aggregate finishes. Its versatility allows for a range of aesthetic enhancements while maintaining structural integrity.